Researchers at the Massachusetts Institute of Technology (MIT) have developed a new manufacturing technique that allows normally brittle and rigid materials to stretch and bend while maintaining their mechanical strength. A remarkable innovation that could lead to the emergence of a host of potentially revolutionary materials.

Humanity regularly relies on extremely strong materials, such as metals and ceramics. These are sometimes capable of withstanding tremendous mechanical stress, making them very useful in a wide range of industries. But they tend to be extremely rigid and not necessarily very adept at withstanding deformation without breaking, like rubber – and vice versa.

This dichotomy exists because these two properties are typically considered incompatible. Typically, creating a very strong material means making big concessions on its malleability, and vice versa. Overcoming this obstacle is one of the biggest challenges facing materials science… and MIT researchers have just taken a step in that direction with a fascinating study, published in the prestigious journal Nature Materials.

A Matter of Structure and Scale

A material's properties typically stem from its chemical composition; the interactions between its individual atoms directly determine its response to different types of stress. For example, a metal is rigid because its atoms are organized into a dense, ordered crystalline lattice. This lattice resists deformation well, but breaks easily when pushed beyond its limit. Conversely, a material like rubber is made up of loosely bonded polymer chains. These chains can therefore unwind and reorganize under stress, making the material stretchable and flexible – but much less resistant in absolute terms.

But playing with the atomic structure, defined by this chemical composition, is not the only way to influence the properties of a material. We can also play with its architecture on a larger scale: we then enter the domain of what we call metamaterials.

Take the example of two objects made of exactly the same material, but organized differently – for example, a flat sheet of cardboard and a corrugated one. The first is flexible and bends easily; on the other hand, the second, thanks to the waves formed by its relief, gains in rigidity and can withstand much greater stresses. In this case, we can consider our corrugated cardboard as a metamaterial. The chemical composition is identical, and the atoms are therefore organized in the same way at the microscopic scale. But at a larger scale, this additional architecture gives it new properties.

A hybrid knit with formidable properties

In their latest study, the MIT researchers took this concept even further by tackling the problem from the other end. Instead of trying to create a strong metamaterial from a flexible base, they attempted to design a flexible product from rigid and brittle constituents.

To achieve this, they drew inspiration from hydrogels—materials made flexible and elastic by polymer chains trapped in a water-based substrate. Using this example, they developed a new construction technique that is almost like knitting.

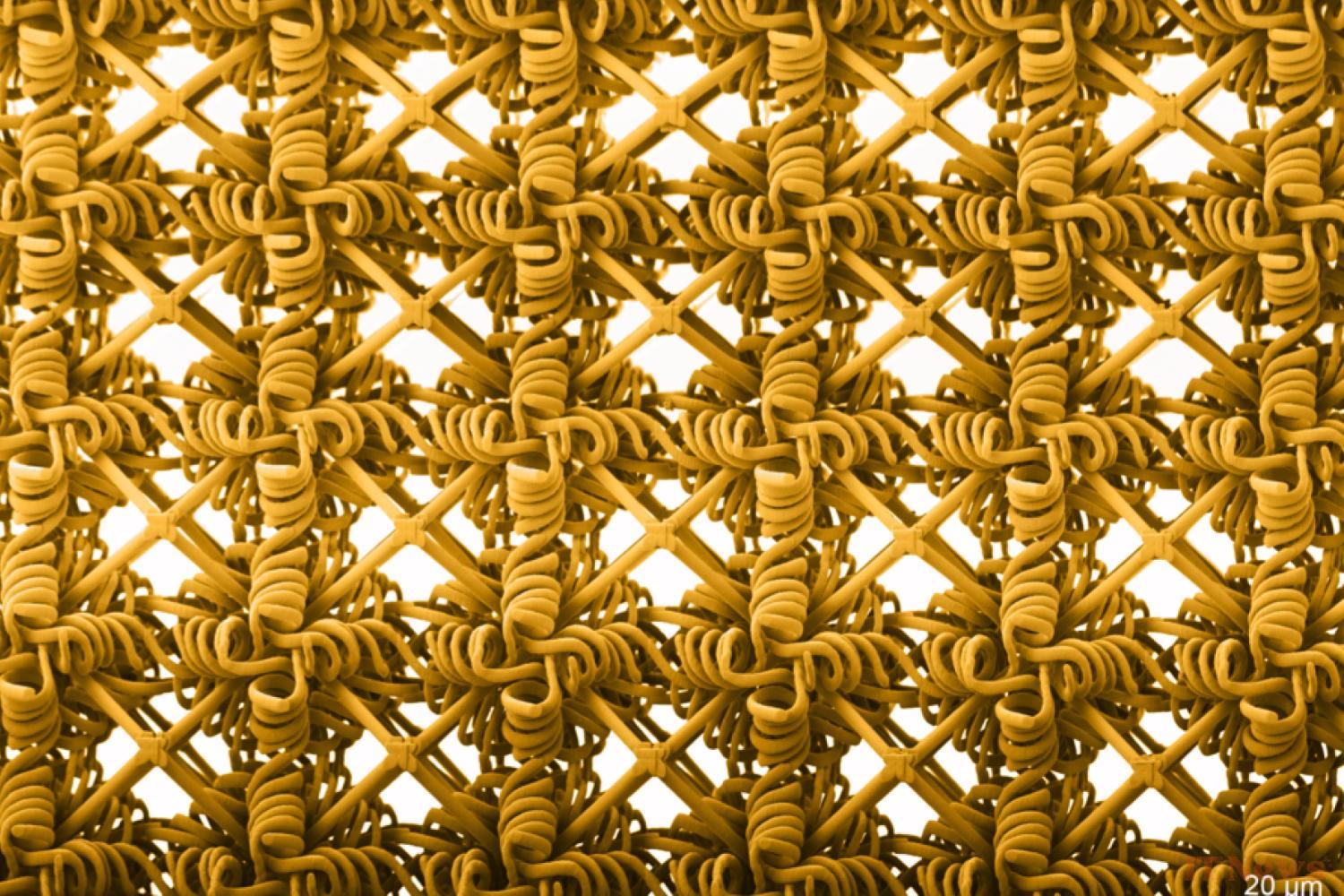

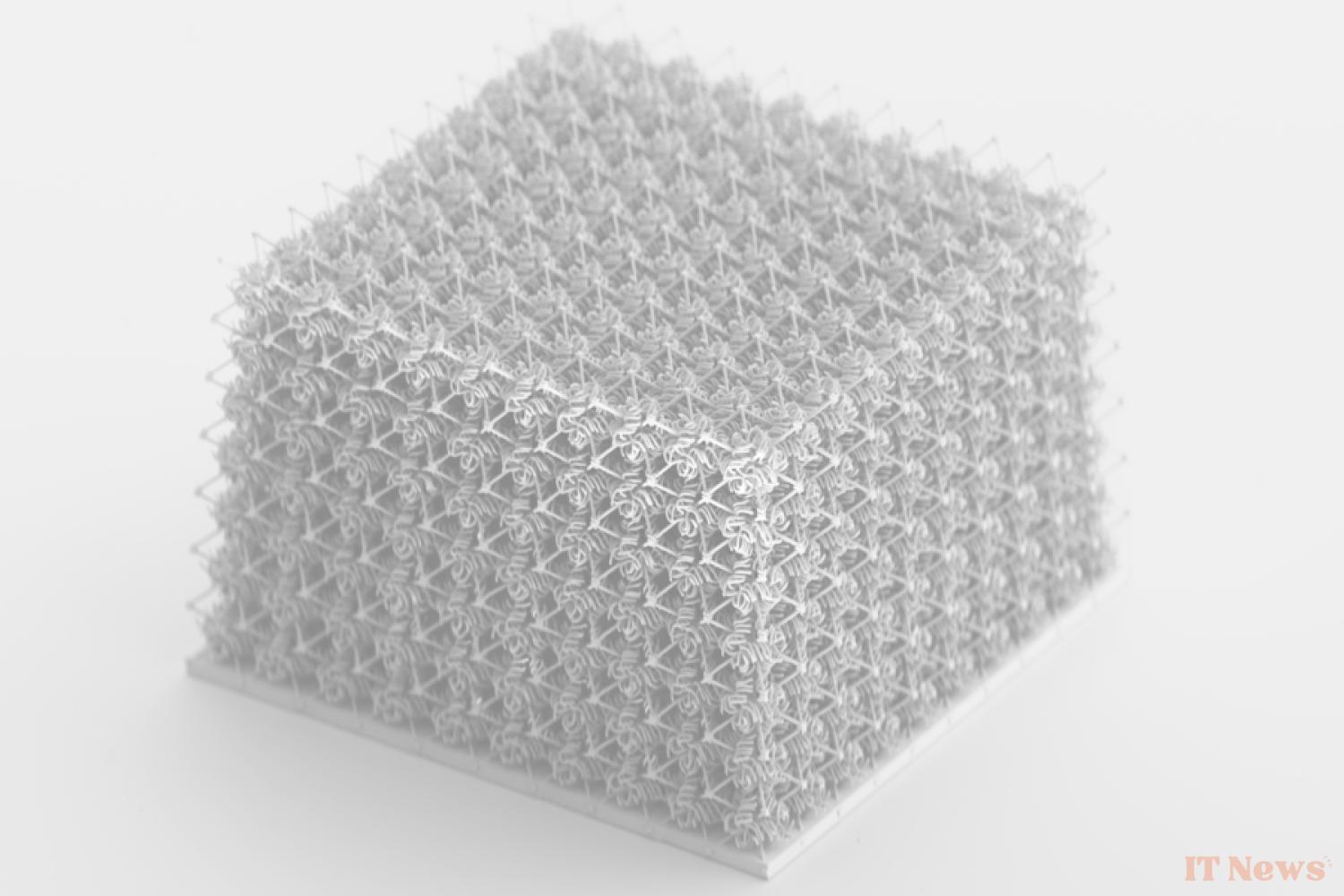

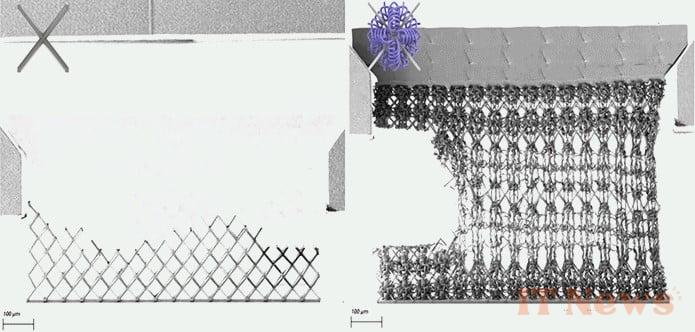

Their approach involves entangling two types of yarn, some strong but rigid and brittle, others flexible but more fragile, within a single coherent network. Inevitably, the stiffest sections will eventually break under the strain – but the authors have found a way to exploit this limitation to their advantage. They introduced structural "defects" at strategic locations to optimize the distribution of mechanical stress in the metamaterial, which has the effect of increasing its overall strength.

"Imagine this woven network like a tangled mess of spaghetti around a lattice. As we break the monolithic network, those broken pieces get tangled, and all that spaghetti binds to the pieces of the lattice," explains Carlos Portela, lead author of the study. "You might think this would degrade the material," says co-author James Utama Surjadi. "But we found that by adding defects, we can double or even triple the dissipated energy. This gives us a material that is both stiff and strong, which is usually contradictory."

They then tested this approach with a lattice made of a polymer similar to Plexiglas. And the results were quite dramatic. While the polymer in question is usually very rigid and brittle, the metamaterial was able to stretch to reach four times its original size, while maintaining very high mechanical strength in the other axis!

A potential that leaves you thinking

This proof of concept is already impressive in itself – but it becomes even more exciting when you start to extrapolate. The researchers believe that with a little work, it will be possible to replicate this approach with even stiffer materials to obtain metamaterials with exceptional properties. “You could print a double-lattice metal or ceramic and benefit from many advantages: they would require more energy to break and their stretchability would be significantly higher,” says Portela.

The icing on the cake is that the potential of this approach is not limited to mechanical properties. In theory, it would even be possible to confer new properties on materials, well beyond the simple dichotomy between stiffness and flexibility.

“So far, we’ve talked about mechanical properties, but what if we could also make them conductive, that is, sensitive to temperature?,” asks Portela. "The two networks could be made of different polymers that react differently to temperature, so that a fabric could open its pores or become more flexible when it's hot and more rigid when it's cold. This is an avenue we can explore right now," he enthuses. "We're opening up new territory for metamaterials." It will therefore be fascinating to follow the results of this work. Once the concept matures, it's quite possible that it could lead to the emergence of new families of metamaterials that could solve currently insoluble problems in a wide variety of industries, from textiles to bioengineering, including semiconductors and advanced electronics. Quite a program!

The text of the study is available here.

0 Comments