New batteries, new engines, and unprecedented on-board technologies: BMW is revolutionizing electric cars. We traveled to the Landshut factory near Munich to find out how the brand plans to get back in the race in a highly competitive market segment.

BMW is one of the most dynamic historical car manufacturers on the electric car market, like Mercedes, for example. The brand markets a wide range of SUVs, but also sedans and even scooters via its subsidiary BMW Motorrad and its astonishing BMW CE 04 and BMW CE 02. To respond to the rapid technological evolution in the segment and fierce competition, particularly from China, BMW is preparing to launch two new models under the banner of Neue Klasse. With once again two versions in the form of an SUV and a sedan. These two vehicles promise, among other things, unprecedented performance in terms of power, autonomy, and charging power.

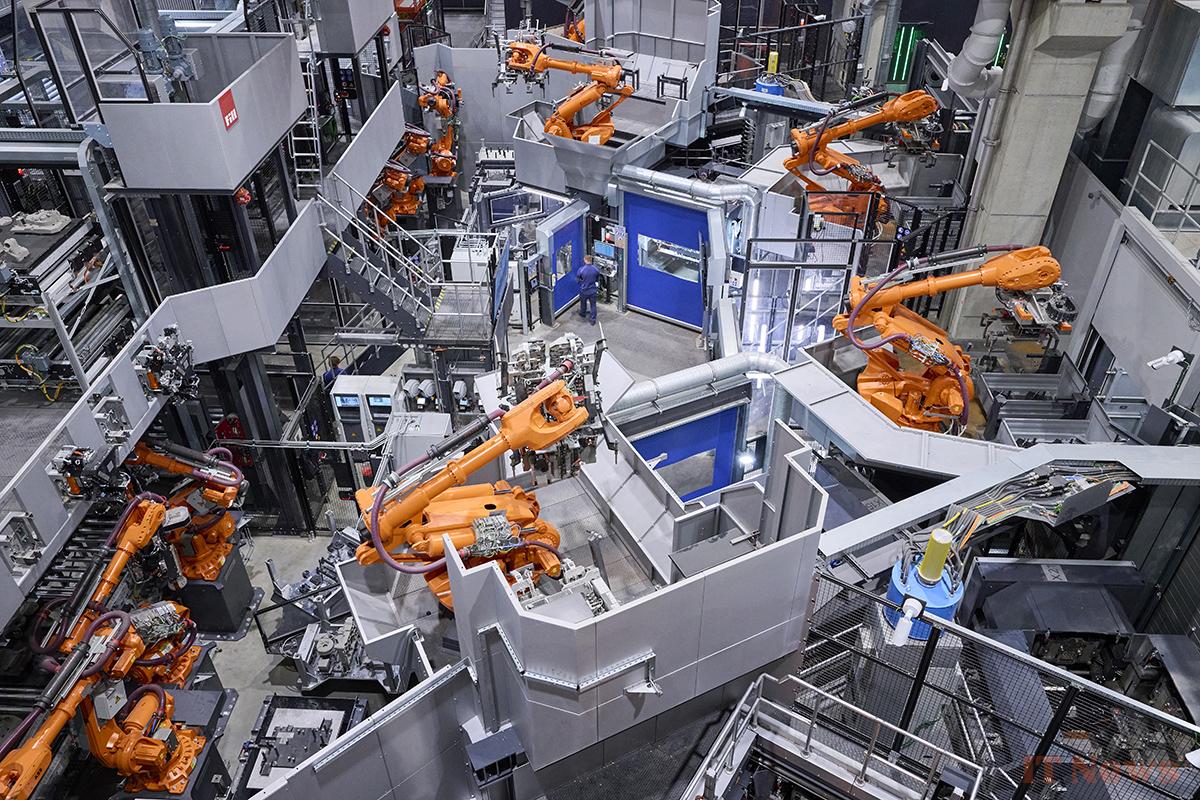

It is therefore in the Landshut factory, a stone's throw from Munich, that we have an appointment to discover the future of BMW in preview. The opportunity to dive into the heart of innovations within the BMW Group's largest component factory in the world. This will be responsible for producing crucial elements, such as electric motors and the battery control unit starting this summer, as we will see later.

A new generation of much more efficient battery high-performance

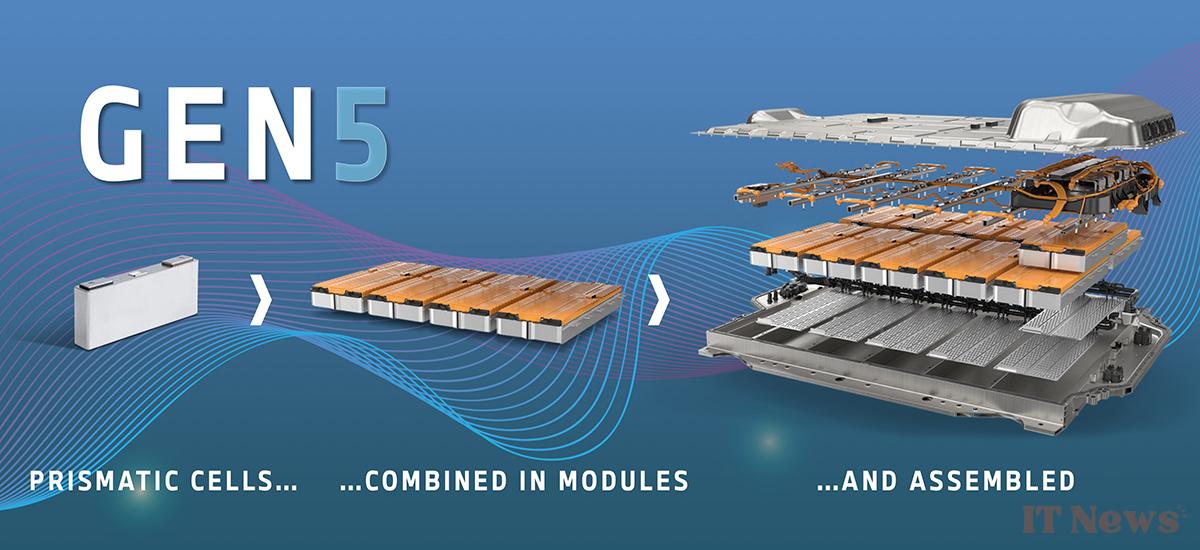

The tour begins with the presentation of the new high-voltage battery developed by BMW. To date, all 15 models in the brand's all-electric range are equipped with the Generation 5 platform, whether it's the "small" BMW iX1 or the imposing BMW iX. Models that are offered with different types of engines and which were therefore not designed specifically for electric vehicles, with all the constraints that this can entail.

These fifth generation batteries have the particularity of using so-called prismatic cells, which are combined into modules before being assembled in this called a battery pack. The same one that will be integrated under the floor of the car and that will power the electric motor(s). Classic then.

However, while this 5th generation boasts some interesting figures, such as up to 701 km of WLTP range claimed by the recently launched BMW iX xDrive 60, it is starting to show signs of weakness compared to the competition. Especially for a premium brand like BMW. So let's move on to the future “Gen 6” battery for the next Neue Klasse, the first models of which are expected at the end of the year, and which we will unfortunately not have the opportunity to see during this day dedicated to BMW technologies.

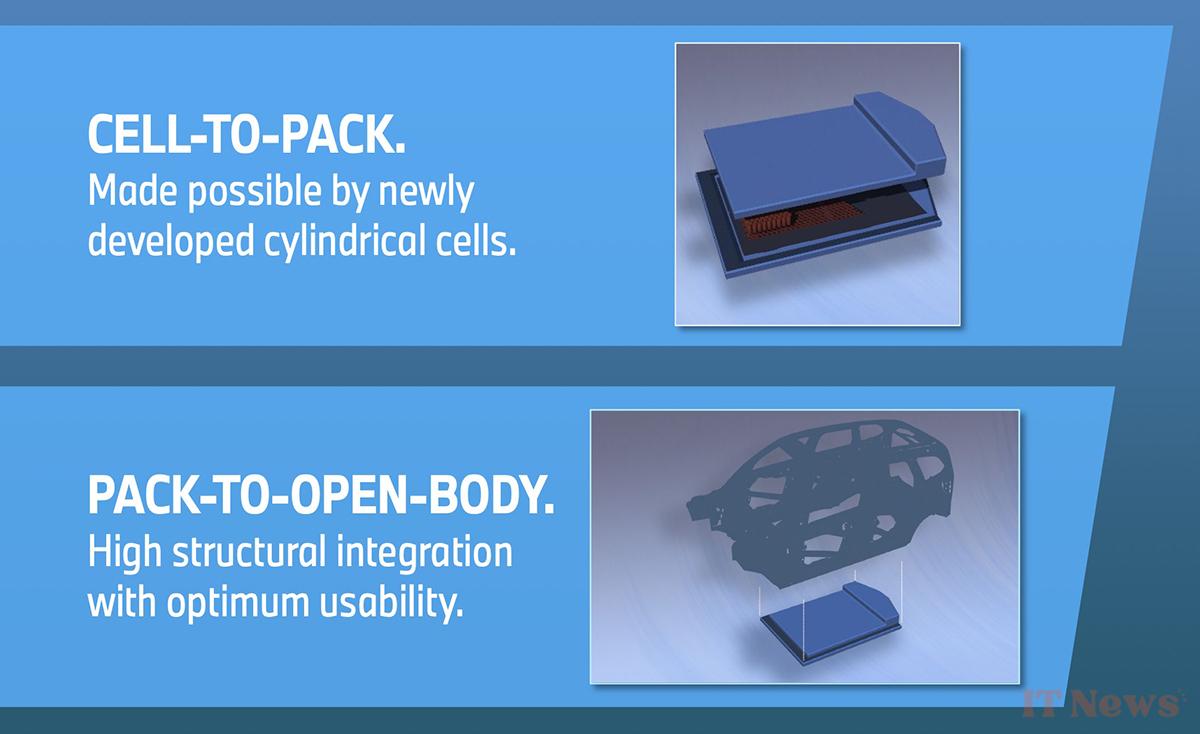

The first notable difference between the fifth and sixth generation batteries is the cells are now cylindrical. They are also reminiscent of the 4680 cells announced with great fanfare by Tesla in 2024. Measuring 95 or 120 mm high and 46 mm in diameter, these cells are announced as offering an energy density increased by 20% compared to the prismatic cells used in fifth-generation batteries.

Another major difference (in every sense of the word), these cylindrical cells are placed directly in the battery pack. This module-free structure reduces the number of components and simplifies the cooling system. These changes also bring productivity and cost gains, BMW experts tell us.

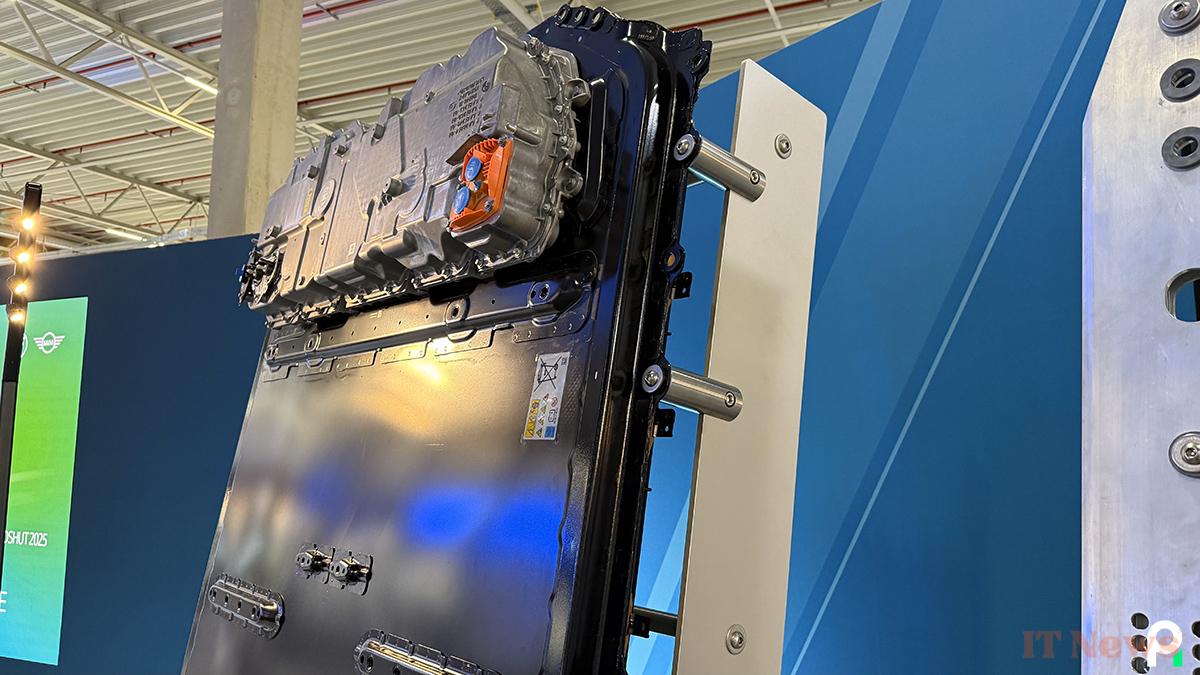

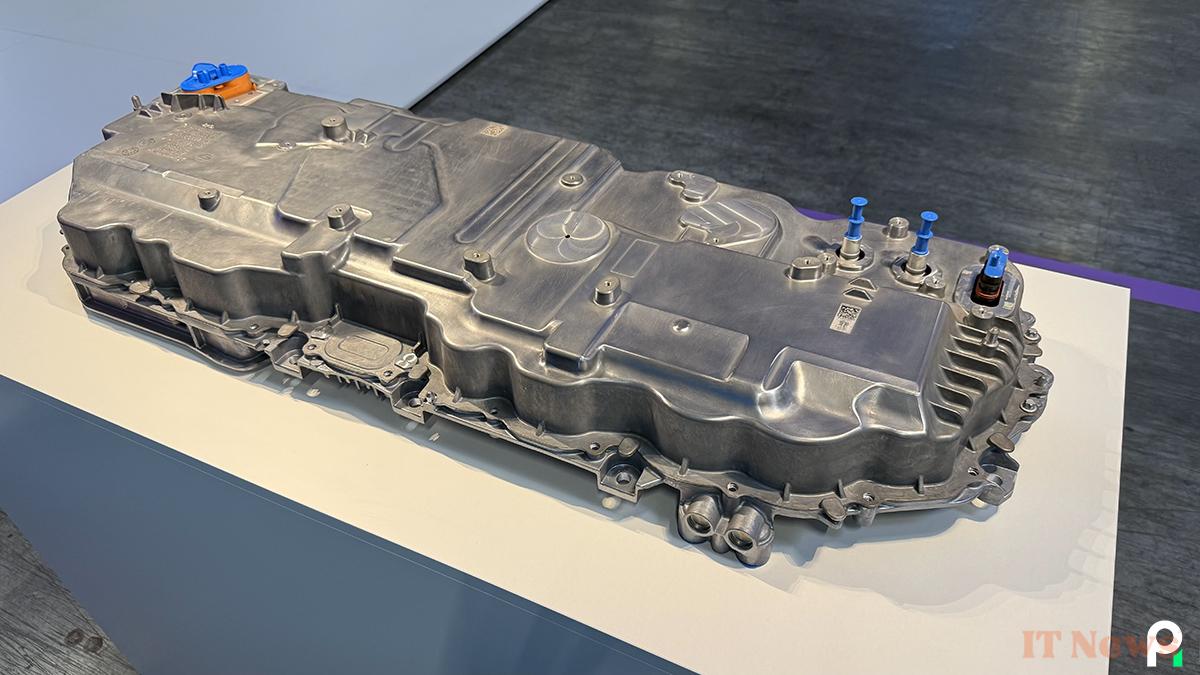

Finally, this so-called Cell-to-pack design (cell to battery) offers space and weight savings that are particularly interesting in an electric car. Just compare the fifth and sixth generations to see how thin the latter is, as can be seen in the photo below.

By the way, it should be noted that BMW still uses third parties for the cells (with three suppliers, including CATL), thus preferring to focus on the other stages of battery production. In addition to its flat design, the new generation battery acts as a structural element with the “Pack To Open Body” integration. Indeed, it is directly grafted under the bodywork, which this time is devoid of the usual metal plate acting as a separation between the two elements. This design once again promises advantages in terms of weight, but also aerodynamics (lower height, equipped cars will benefit from a lower Cx), all with roominess that should improve further.

Moreover, if these new features promise real progress in BMW's next electric cars, the first models of which are expected by the end of the year, we remind you, we took advantage of our visit to the Landshut factory to ask the brand's managers about other technologies that regularly come up in the news. LFP batteries? For BMW, the NMC is more suited to the needs of its customers, but the sixth generation batteries will have no trouble accommodating other types of cells depending on the model.

As for the solid battery, Dr. Joachim Post, member of the BMW Group Board of Management, tells us that producing a prototype powered by this type of battery is clearly nothing impossible today. On the other hand, it is difficult to envisage large-scale production at a reasonable cost in the medium term.

Finally, the topic of recycling was also addressed during our meeting with the managers and experts present. In addition to the notable absence of rare earths in its electric cars and the use of renewable energies, the future Neue Klasse is part of a circular economy with two key words: recycling and reuse.

Thus, the molds for the electric motors in which the aluminum is cast are, for example, made from sand. Although they are destroyed at the end of the process, the base material is recovered to create new molds.

In the same vein, aluminum scraps are also recovered and melted to mold other engines in a high-temperature electric furnace.

Furthermore, BMW has formed a partnership with SK tes, which recovers end-of-life batteries in order to extract cobalt, nickel, and lithium, for example. These components are then integrated into the supply chain for the manufacture of new batteries.

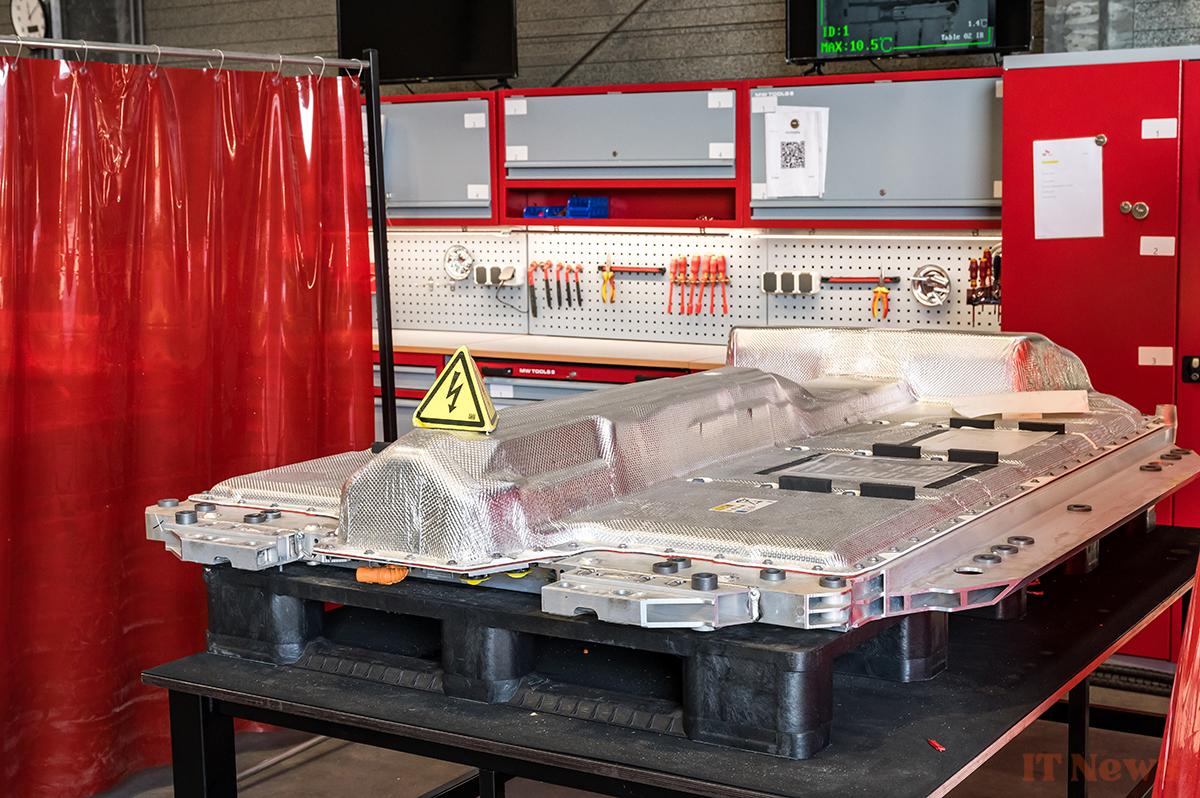

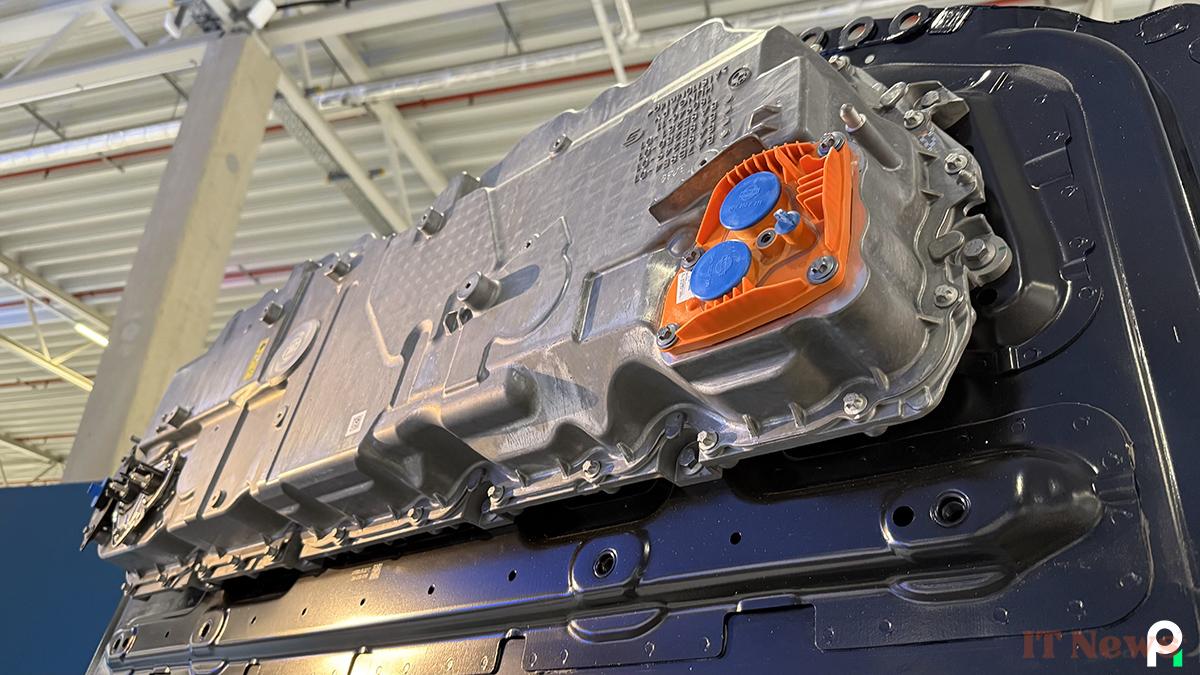

BMW Energy Master, the brain of the battery

As thin as it is, the most attentive will have noticed a protrusion on one side of BMW's sixth-generation battery. This is actually the Energy Master, which contains all the intelligence of the sixth-generation battery.

Produced in the Landshut factory by some of the site's 400 robots (82% of production is automated), the Energy Master manages functions such as powering the car's comfort features and delivering the energy stored in the battery to the motor(s). It is also a key element for thermal management, power management during battery charging operations, bidirectional charging, which will finally make its debut at BMW, and the automatic switching from 400 Volts to 800 Volts depending on needs. We'll come back to this later.

Thanks to the intelligence of the Energy Master, BMW's sixth-generation high-voltage battery will be able to offer the same flexibility as the current generation, in order to equip all of the brand's future 100% electric models. From the smallest to the largest, with the different capacities required, both in NMC and LFP if the latter were to be offered, for example.

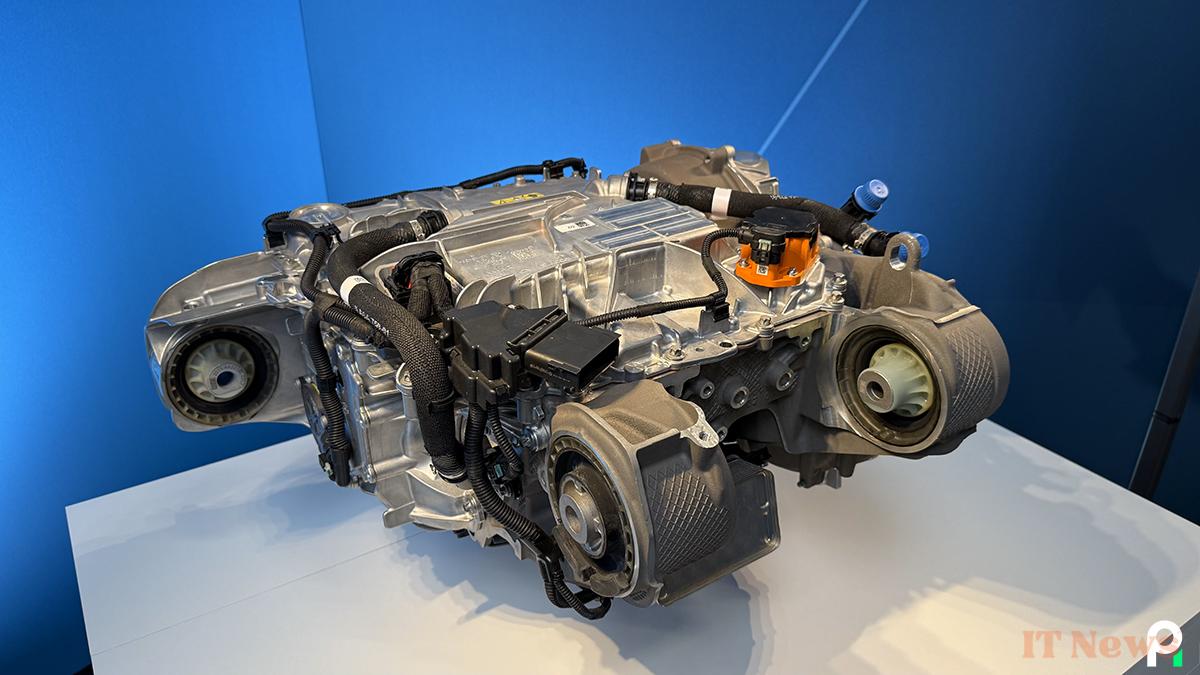

A new electric motor designed by and for BMW

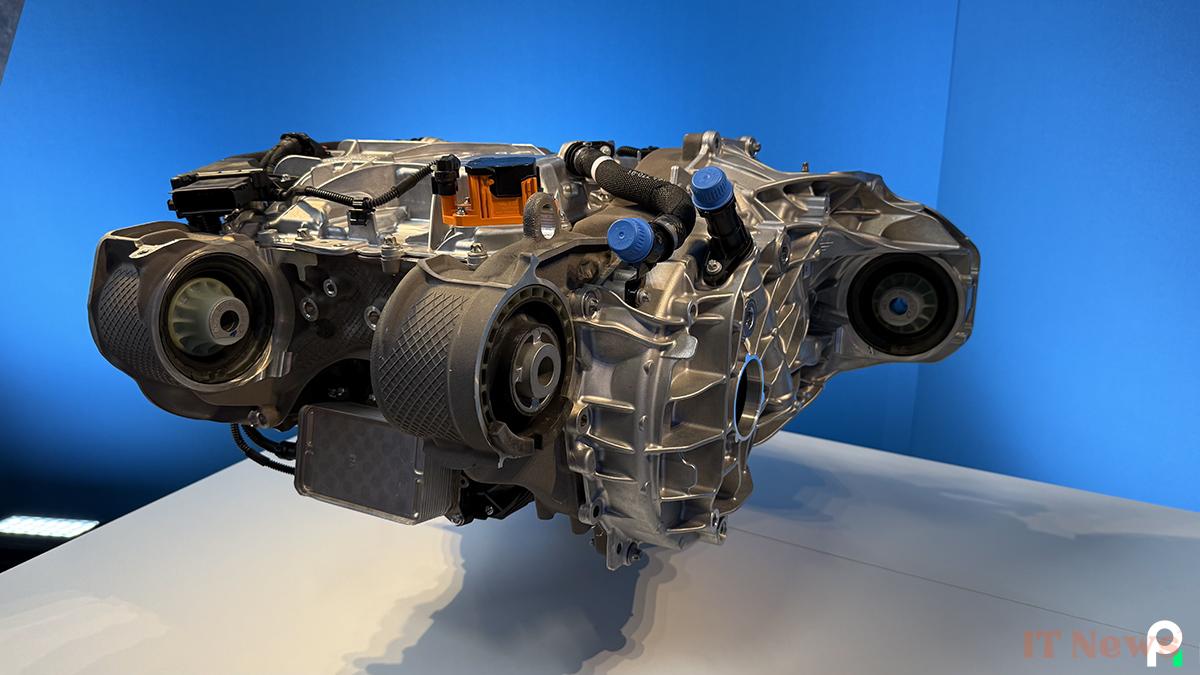

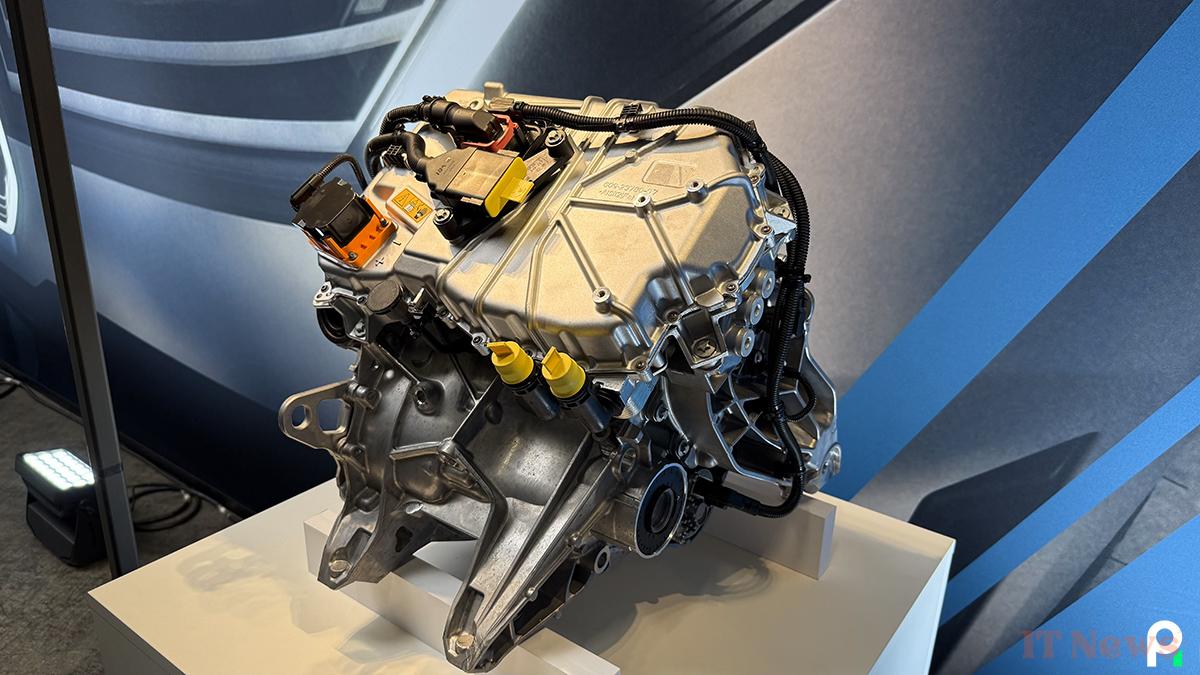

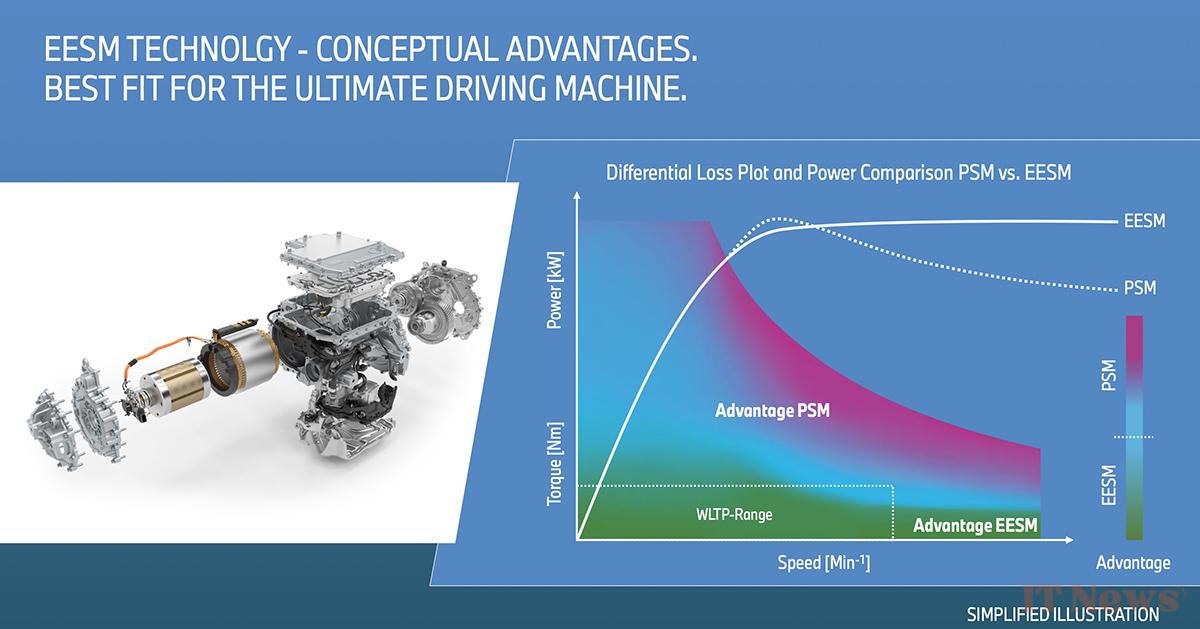

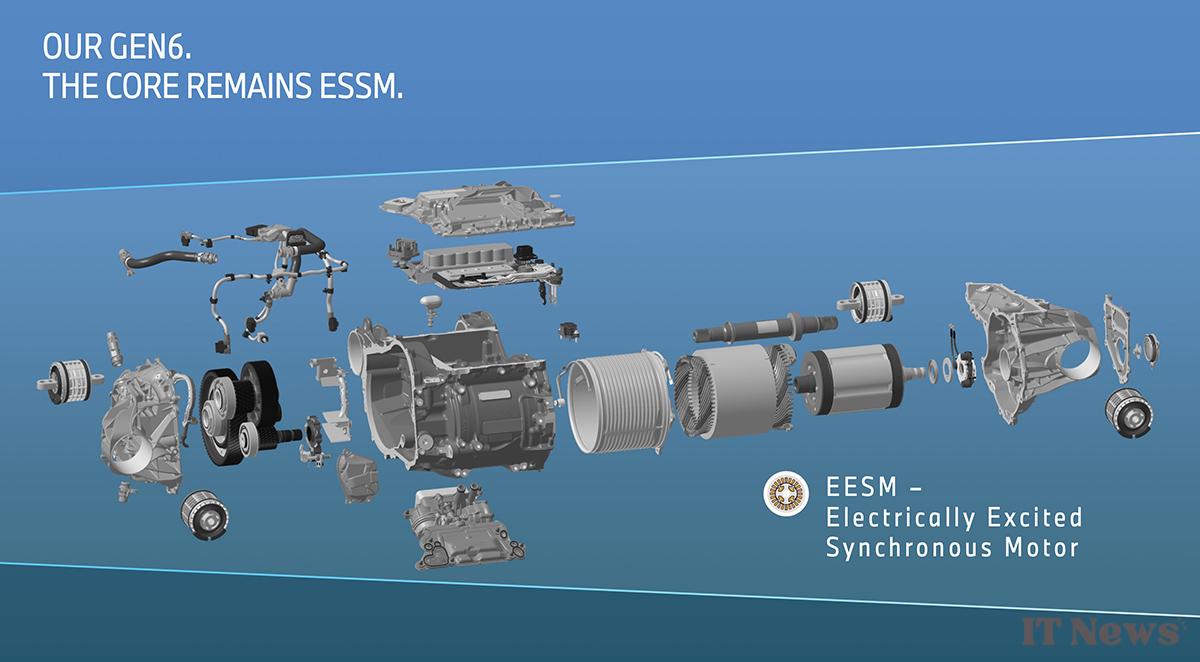

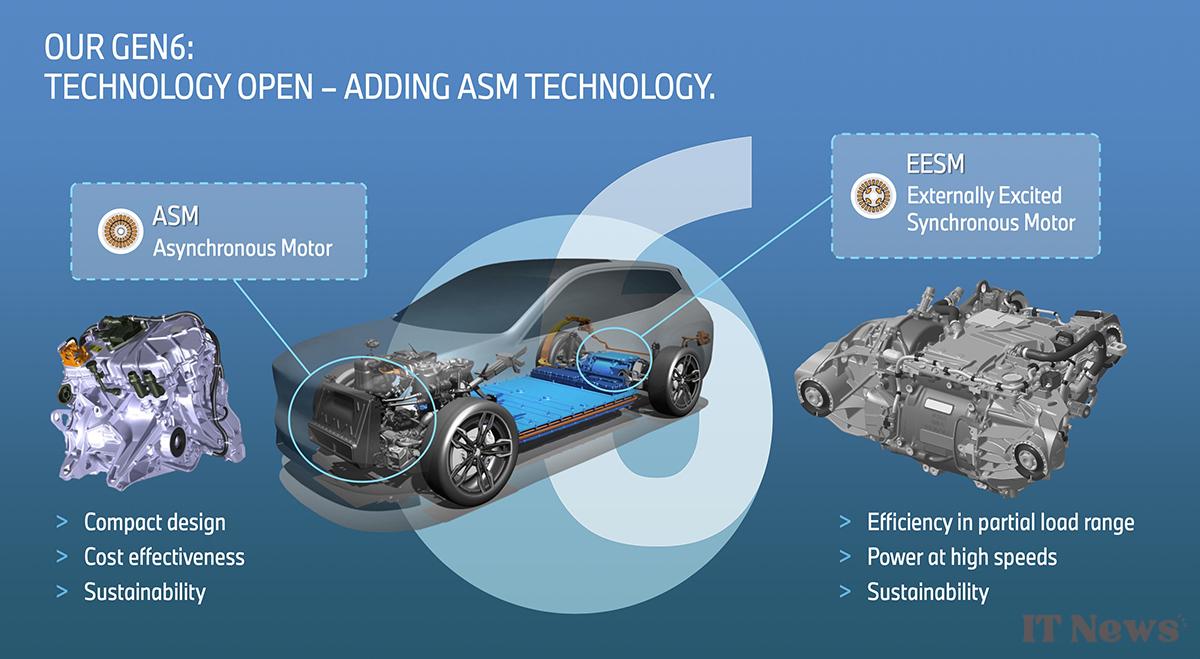

The Gen6 battery isn't the only major new feature expected in the upcoming BMW Neue Klasse. BMW has also developed its own electric motor in-house. The manufacturer has once again opted for an EESM synchronous motor. This technology is already found in all of its current electric cars, with power outputs ranging from 120 kW to 360 kW, as well as in the Spectre, Rolls-Royce's first all-electric car. This main motor is positioned on the rear axle and paired with an asynchronous motor (ASM) at the front for four-wheel-drive models. A proven architecture that is also found in Tesla in particular.

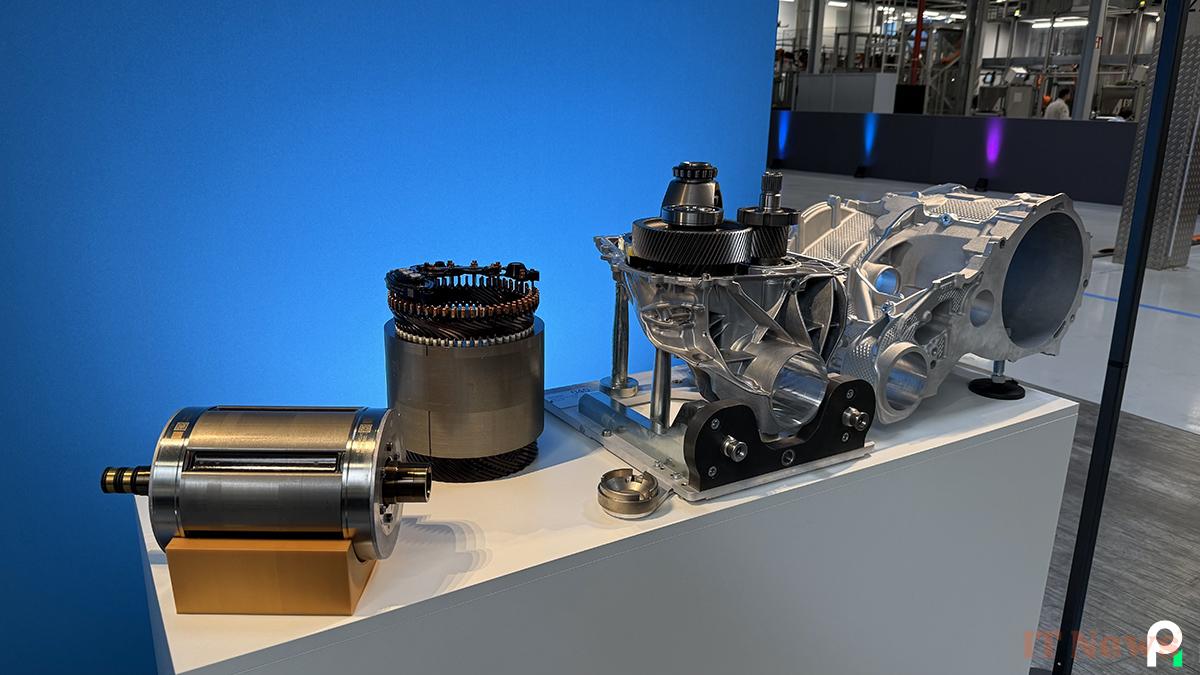

Unlike the ASM engine, which is supplied by partners, the EESM engine was developed entirely in-house by BMW, which is also responsible for its production. This one has the advantage of being relatively compact with a design that has been simplified by integrating elements such as the rotor, the stator and the gearbox for example.

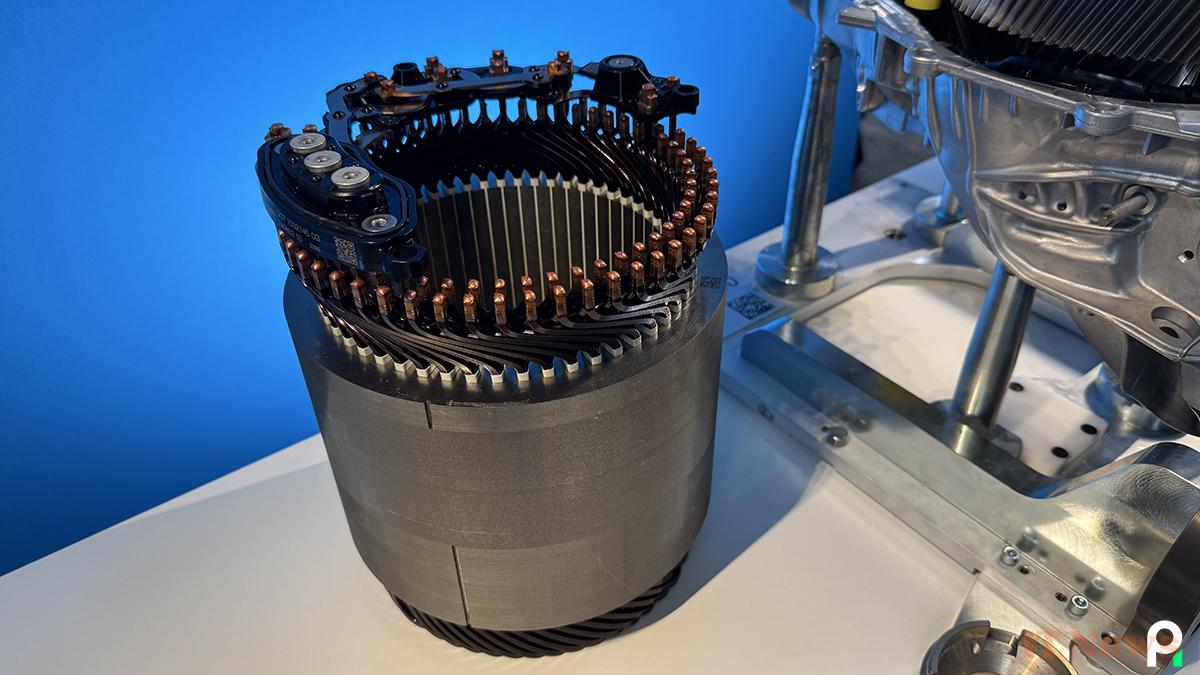

Rather than using permanent magnets as is generally the norm, the rotor's magnetic field is generated here by coils, which are powered by direct current. In doing so, the system can more precisely adapt the rotor's magnetic field intensity according to power demands.

When asked about the advantages of this new Gen6 EESM engine, BMW engineers put forward several elements: stable power output at high rotation speeds, significant efficiency at medium revs, and very high torque, particularly when using Boost mode.

Devoid of rare earths as was already the case at BMW, this new unit is 10% lighter, thanks in particular to a cast aluminum structure in the foundry at the Landshut plant. Engineers report a 40% reduction in energy losses and a 20% drop in production costs.

How? First, by adapting components such as the rotor, stator, and inverter for the new 800-volt architecture that we were eager to see at BMW. The oil and water cooling system has also been revised, as has the gearbox. By reducing friction, the engineers have managed to reduce the noise generated by the EESM engine. Finally, the inverter had to be extensively modified to accommodate the 800-volt platform. Indeed, it is responsible for converting the direct current from the high-voltage battery into alternating current to power the electric motor. In addition to the use of silicon carbide semiconductors, which are more efficient according to experts (and we tend to believe them), the inverter has also been fully integrated into the electric motor housing.

Finally, the new powertrain offers greater modularity than on a Gen5 xDrive model. Indeed, while the latter allowed the integration of up to two motors, the sixth-generation platform will be able to offer up to four electric motors. This includes BMW's sportiest M Series.

What advantages for future customers?

As mentioned above, the Energy Master, which is paired with the sixth-generation battery, can handle different charging powers. Indeed, BMW is finally adopting the 800-volt platform, which is a real game-changer on long journeys. We had already noticed this during our various tests, whether it was the new Porsche Taycan (https://www.phonandroid.com/essai-porsche-taycan-2025.html), the Audi Q6 e-tron, or the Hyundai Ioniq 6, for example.

By the way, Mercedes is also expected to integrate this technology later this year with the launch of the new electric Mercedes CLA. And while some Chinese manufacturers such as Xpeng already offer it, Tesla is famous for completely ignoring it, even on its high-end models. This didn't stop the American brand from significantly increasing its prices at the beginning of the month (https://www.phonandroid.com/tesla-mauvaise-nouvelle-les-prix-de-ces-voitures-electriques-senvolent.html#:~:text=Indeed, the manufacturer comes with unprecedented advantages.&text=In the space of one, or +€17,000.).

But let's get back to the next BMW Neue Klasse. This time, the electric cars will be able to accept higher power and promise a 30% faster charging speed compared to a current model equipped with a fifth-generation battery. Enough to reduce break times at DC terminals that are capable of delivering more than 250 kW.

Furthermore, with better cell density, reduced battery weight, and improved cx, BMW's next electric cars promise to be more efficient (BMW announces 20% better), with a 30% increase in range. All this with costs reduced by up to 50%. It remains to be seen whether this will translate into lower vehicle prices? When asked about the issue, the brand's representatives dodged the question. See you in the fall to find out more.

0 Comments