The front of the Manufacture française du cycle, on April 8, 2025, at the start of the Tour des Pays de la Loire.

The MFC test laboratory. This is where the frames and various components are tortured to ensure they meet current standards, or even exceed them.

Like this Sunn mountain bike frame, the parts undergo between 100,000 and 350,000 operating cycles. During the development phase, engineers even push them to breaking point to know when they will give way.

MFC doesn't just manufacture Nakamura and Sunn models, two brands owned by Intersport. It also has third-party clients, such as Vélib', the self-service bicycles in the Paris region.

1,400 bicycles leave the factory every day. The bare frames are just waiting to be equipped.

The first step is painting the frames. They are manufactured in Asia, but painted in Machecoul. The operator places them here on the line.

The painters only paint the least accessible parts. The rest is done using a powder system that adheres to the frame using an electrostatic process. Everything then goes into the oven for 5 minutes at 180° to set the paint. The whole process takes place in a closed circuit, the paint that has not finished on the frame is sucked up and reinjected into the system.

The MFC being an approved operator, it affixes a unique identification number (in this case a BicyCode) to the bikes. It will then be covered by the varnish to make it impossible to remove.

The decoration is entirely applied by hand. It is mostly women who handle this very precise task, which requires up to three weeks of training. Women represent 48% of the Machecoul site's employees.

Wheel manufacturing is even more technical. There, the operator attaches the hub and spokes to the rim. You can't miss the spoke crossing, designed to provide the best possible rigidity to the wheel.

This machine, the result of a collaboration between MFC and wheel manufacturer Mach1, automatically completes their assembly. An algorithm thus determines the correct tightening to avoid warps, jumps, and offsets. 80% of the rims and spokes used here are made in France.

The final step in wheel manufacturing involves fitting the rim tape, inner tube, and tire. Here again, the process is very technical. For example, you mustn't screw up by wedging the inner tube, which could cause it to explode during inflation; causing a 120 dB detonation that was dangerous for the eardrums.

From each trolley of wheels mounted, three copies are taken at random to control the quality and to be able to act if a problem is detected. There are a total of 14 wheel assembly lines at the MFC.

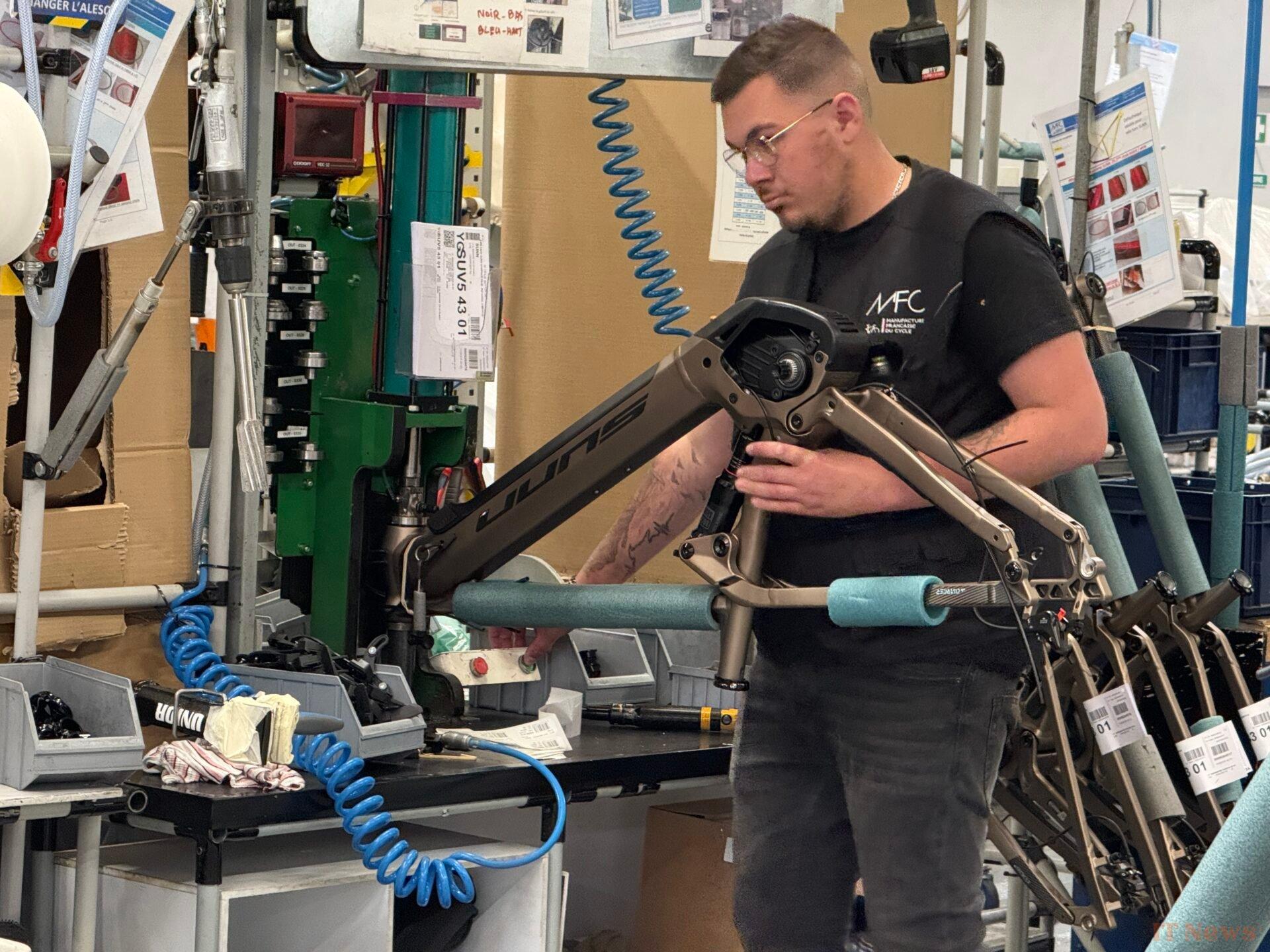

Once the frame is painted and varnished and the wheels are mounted, we can move on to the actual assembly of the bike. Here, a Sunn electric mountain bike on which the motor has just been installed.

Assembling a bike is an art, and e-bikes even more so. Here, the operator inserts the cables and hoses into the frame so that they are not visible. Anyone who has ever tried to do this on their own bike knows the skill and patience it requires.

The sheaths that arrive at the MFC have standard sizes, so they must be cut to the correct lengths depending on the bike model they will be fitted to.

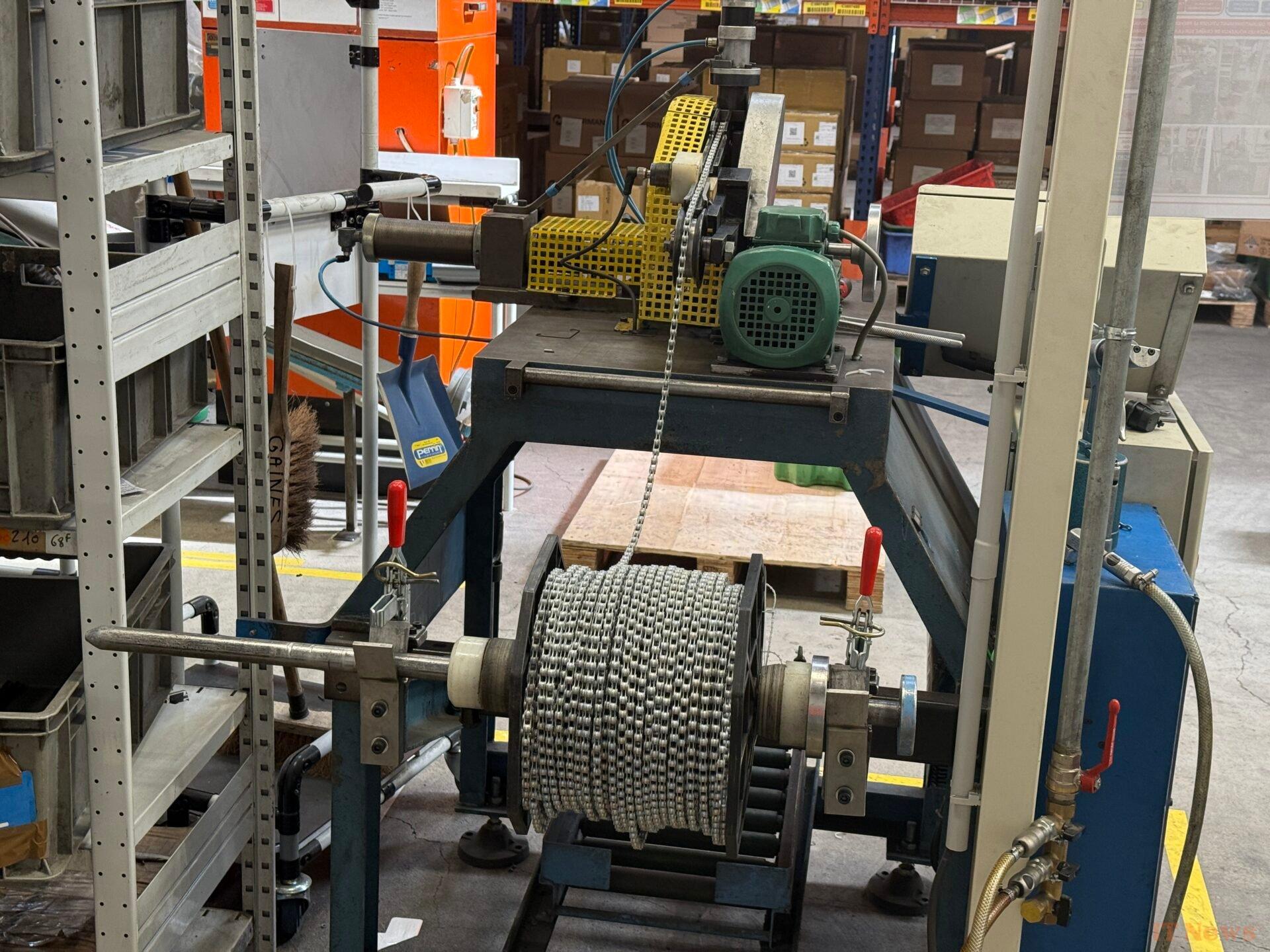

The same goes for chains, which are delivered in reels. They are also cut to the correct length before being fixed between the chainring and the sprocket by a quick release.

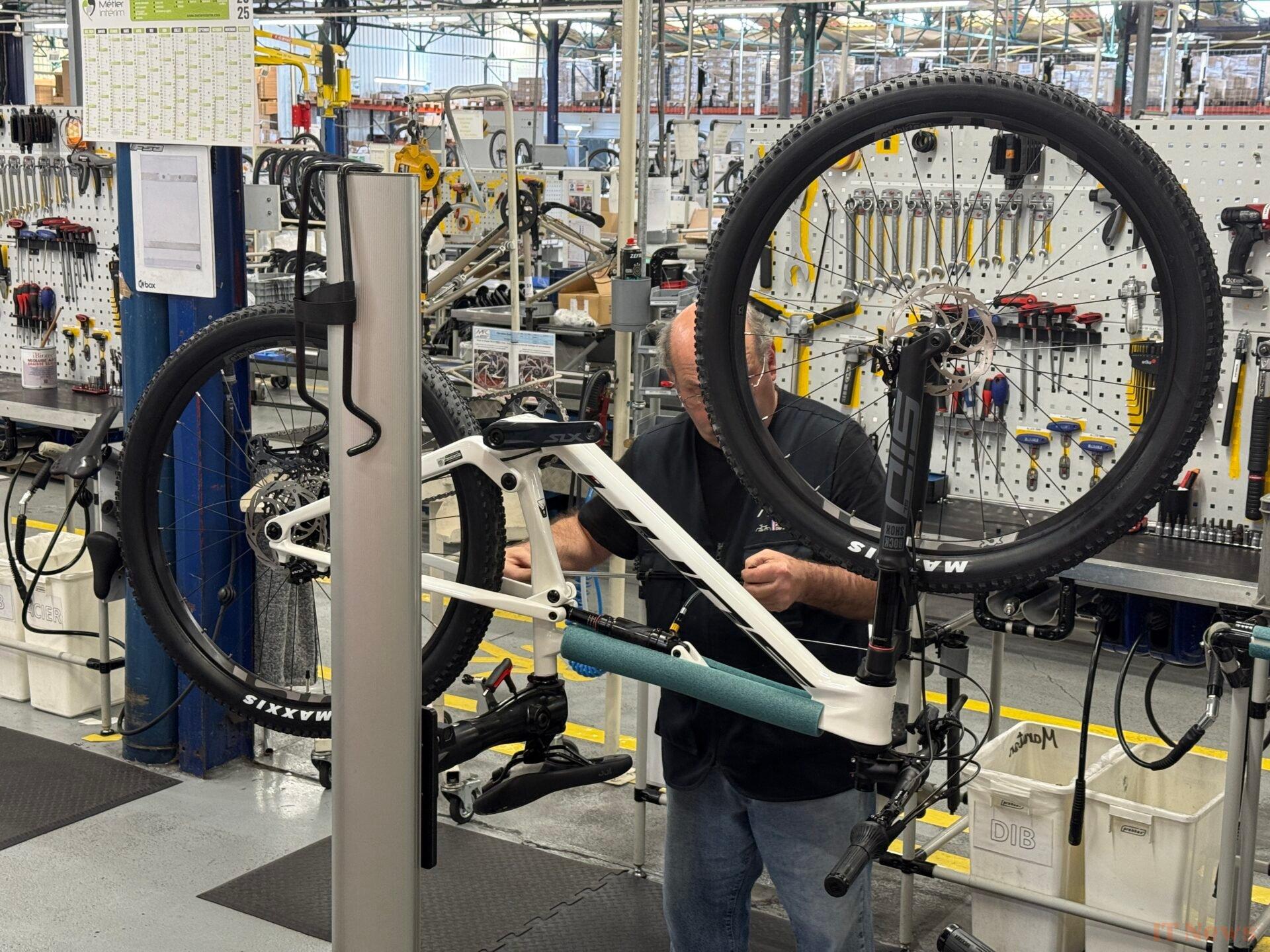

The frames slowly move along the production line to be equipped with their other components one by one. At the end, the operator uses this red support supported by a hydraulic arm so as not to have to bear the weight of the bike. A repetitive movement that would be fatal for his back.

Some more technical or high-end bikes do not go through the assembly line, but are entirely assembled by a single operator. He does everything from A to Z, which means his expertise is the most advanced within the MFC.

Of the ten assembly lines that make up the MFC, the most recent, designed in 2022, is overhead. This €300,000 investment allows the operator to manipulate the frame as they wish and turn it around for greater comfort. The 15 to 25 people who work on this line take between two and four minutes to fully assemble a bike, depending on its degree of complexity. That's a testament to the performance.

All bikes are checked as they leave the line. The operators roll them and connect their motor to a testing tool to ensure everything is in order before packaging them.

All the parameters of the motor and its assembly are checked using dedicated software. Here, an Ananda model is on the test bench.

Before shipping, the bikes are prepared for packaging. The handlebars are aligned with the frame and the tubes are protected from impacts.

Removing the front wheel has made it possible to reduce the size of the boxes.Once packed, the bikes are placed on this platform, an interface with its sister company LSL (Sports and Leisure Logistics). It manages the 30,000 m2 of storage.

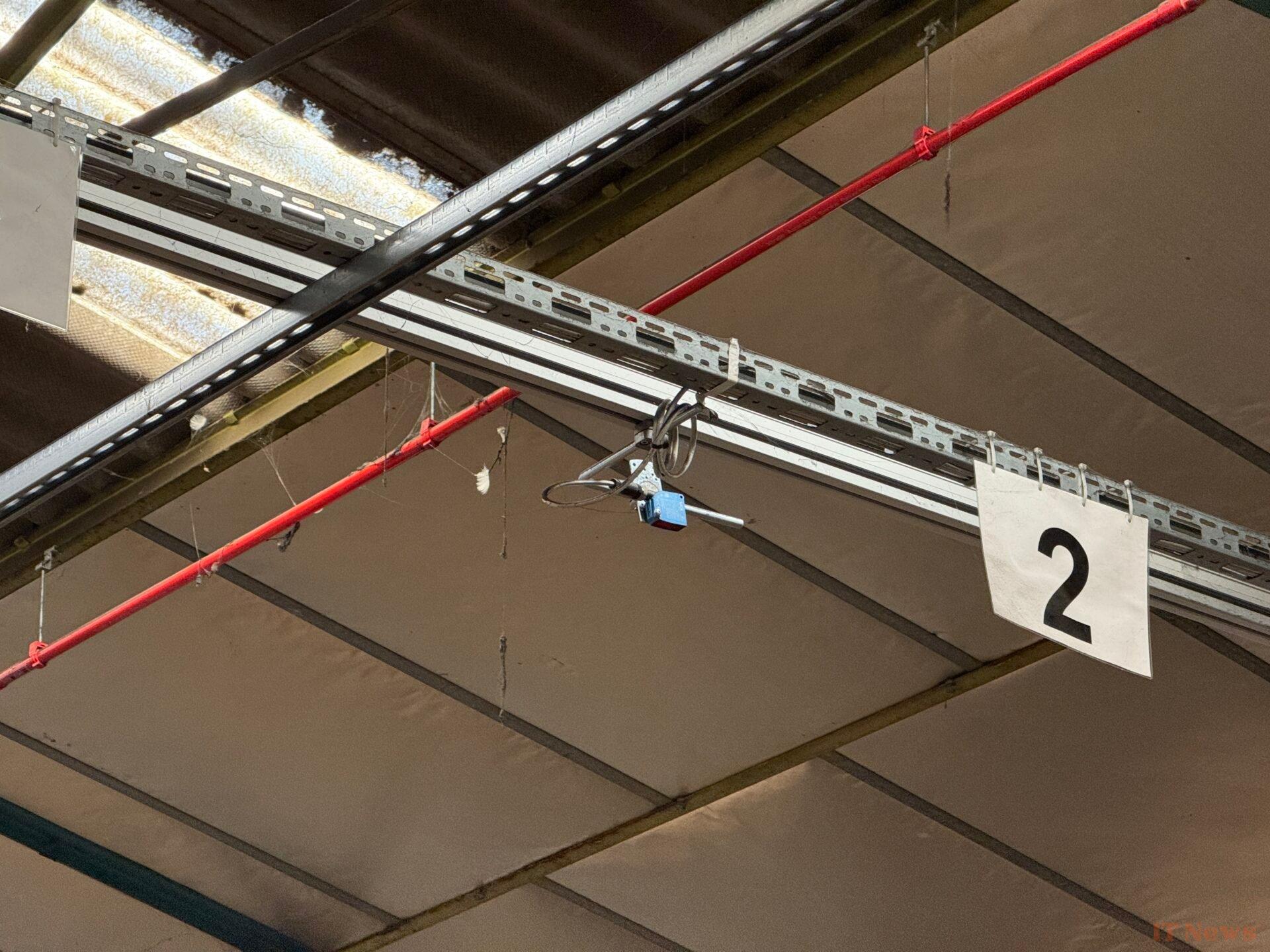

This blue detector, placed at the end of each row, knows exactly when it's full. When it is, the AGVs (automated guided vehicles) come and collect the boxes and transport them to storage. They guide themselves automatically using the white beacons placed all around the platform.

0 Comments