Interlune is a startup that bills itself as a lunar mining specialist. Among its main sought-after elements is helium-3, and its demand is growing on Earth to meet the needs of numerous industries. "Rare on Earth but abundant on the Moon", as Interlune presents it, this gas has become essential in the production of semiconductors.

To extract helium-3 on the Moon, Interlune has designed a gigantic excavator capable of ingesting 100 tons of rock per hour. The prototype was co-developed with Vermeer, a global manufacturer of industrial and agricultural machinery. The two announced a co-development partnership on May 7, which will lead to the production of other machines in the future.

Last year, the two companies already discussed their joint work by unveiling a miniature version of their prototype. Designed for continuous operation, it differentiated itself from other traditional excavation systems by digging trenches and raising large quantities of dust. Interlune and Vermeer's testing takes place in a cryogenic laboratory located near Interlune's headquarters in Seattle.

Its co-founder and CEO, Rob Meyerson, stated in a press release that the reliability and performance standards to meet the demands of the lunar environment were "unparalleled". This will promote the expertise of partner Vermeer, which "has a tradition of innovation and excellence that goes back more than 75 years, making it an ideal partner for Interlune," the boss declared.

A complete range for excavating helium on the Moon

“The high-speed excavation required to extract large quantities of helium-3 from the Moon has never been attempted before, let alone with such efficiency,” said Gary Lai, co-founder and chief technical officer of Interlune. “Vermeer’s response to such an ambitious mission was to act quickly. We are very pleased with the results of the test program to date and look forward to the next phase of development.”

The other machines are expected to address the other steps in the process needed to extract helium atoms. After the excavation, it will be a matter of sorting, extraction, and separation, the tests for which are currently underway, announced Interlune.

The race to extract helium began in 2010, when the United States first warned of a definite shortage on Earth. Although helium is the second most common element in the universe, Earth is particularly deficient in it. With the advent of semiconductors etched in less than 5 nm, helium has become the only viable option for the smooth running of certain key production steps.

Why is helium so important in semiconductor production?

The reasons for this gas's popularity relate to its use as a coolant, to stabilize the temperature of silicon wafers during etching procedures. In addition to very good thermal conductivity, it is an inert, non-reactive, and lightweight gas. It allows for the creation of ultra-clean atmospheres with no risk of oxidation.

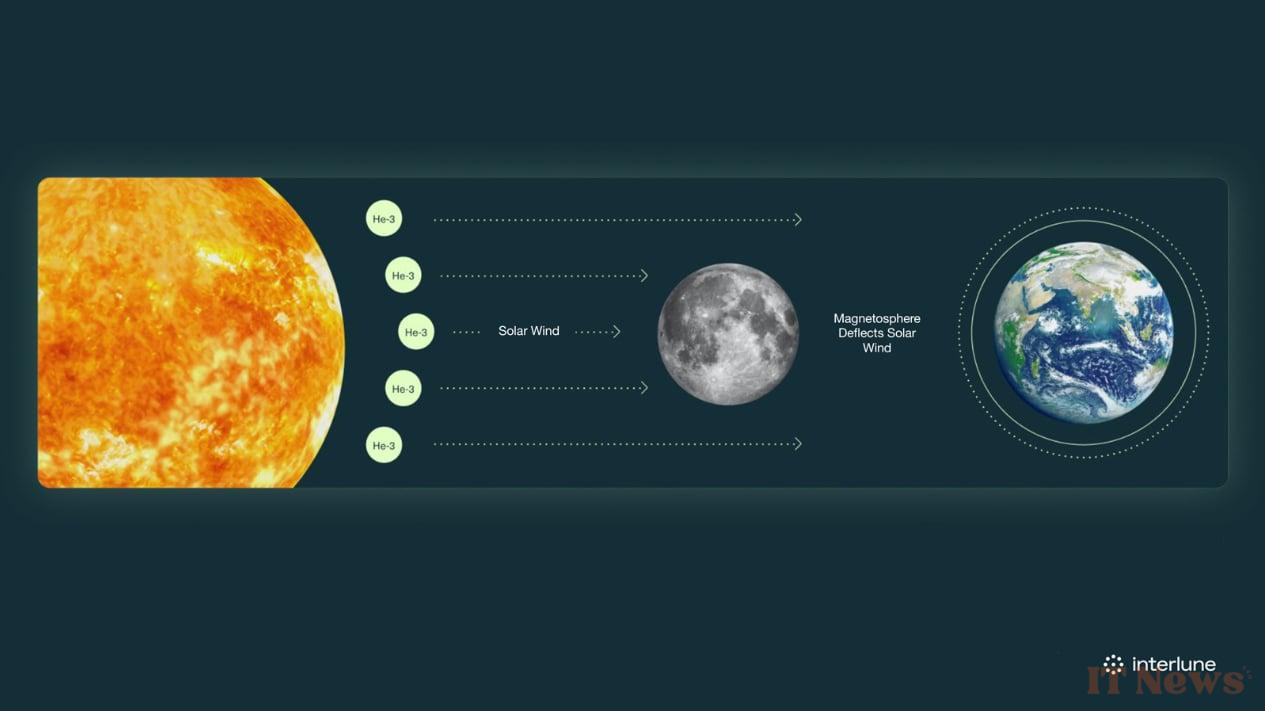

If Earth lacks it and the Moon is particularly rich in it, it is because helium-3 is found in large quantities in the solar winds emitted by the Sun. The isotope cannot reach Earth because of its atmosphere and its magnetic field, which deflect the particles. This is not the case for the Moon. Thus, the dust on the surface of the Moon, called lunar regolith, would be loaded with large quantities of it, particularly in the "lunar seas".

Source: Electrek

0 Comments